By Hazel Scott

Alabama State University

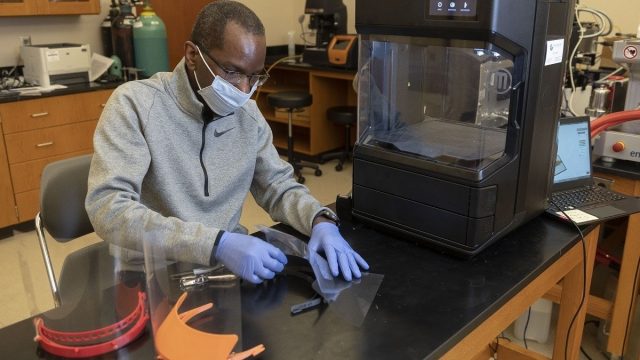

Two Alabama State University professors have joined the fight against the COVID-19 pandemic by using their personal 3D printers to make medical face shields for health care workers who are in desperate need of protective gear.

Dr. Derrick Dean, professor and coordinator of Biomedical Engineering, and Windham Graves, assistant professor in the College of Visual and Performing Arts, decided to get into the battle for one reason – to help.

“I know there is a need in the community, and it looks like it’s going to stay difficult to get personal protective equipment for some time, and I have the tools to help,” Graves said.

Dean echoed Graves’ sentiments.

“This is a tangible effort that makes a real, meaningful contribution and that’s what I’m all about and that’s what the university is all about,” Dean said. “This is a great opportunity for me to connect my passion with a purpose, for when those two connect, we’re destined to make a positive impact. It is very fulfilling to be part of this effort.”

The clear plastic face shields are worn over face masks to give an added layer of protection because they also cover the eyes. Health care workers in Montgomery and staff in assisted living facilities, counseling centers and paramedical organizations will receive the shields and masks.

“These facilities are least likely to have these types of supplies on hand,” Graves said.

Graves; his wife, Sarah, and their friend Elisabeth Palmer have completed 50 face shields and are working on 50 more. The team also is producing cotton face masks.

“We have made 86 face masks and are working on another 100 to be done by the end of the week. Hopefully we can stay on or above that schedule until the need abates,” he said.

Graves has delivered 30 shields and 74 masks.

Dean’s efforts are headed by Montgomery Fighting COVID, a nonprofit that produces face shields. That group, he said, delivered a small batch to Jackson Hospital and more than 50 shields to the Baptist Health System.

“I was connected with them through TechMGM,” Dean said.

So far, Dean has made six face shields and is focused on making 20 more for the group.

Both professors make the shields while juggling their regular work. Graves spends anywhere from three to 10 hours on his projects. “It depends on the day how long I spend making the shields and masks. But it’s getting more efficient as we figure out ways to streamline production,” Graves said.

Dean allots 10-12 hours while multitasking his day. “The printers run about 18 hours per day during this project,” he said.

Donations are supporting Graves’ and Dean’s volunteer work by contributing fabric for the face masks and laminator sheets for the shields. But he is running out of supplies.

“We have done a call on Facebook and have contacted friends and loc al artists that we know. We are hoping that this will reach more people who might have materials they can donate.”

Donations can be made through Amazon or by emailing him.

“Any unused materials will go to support visual arts students or local nonprofits that are making shields for local hospitals,” Graves said.

This story originally appeared on Alabama State University’s website.